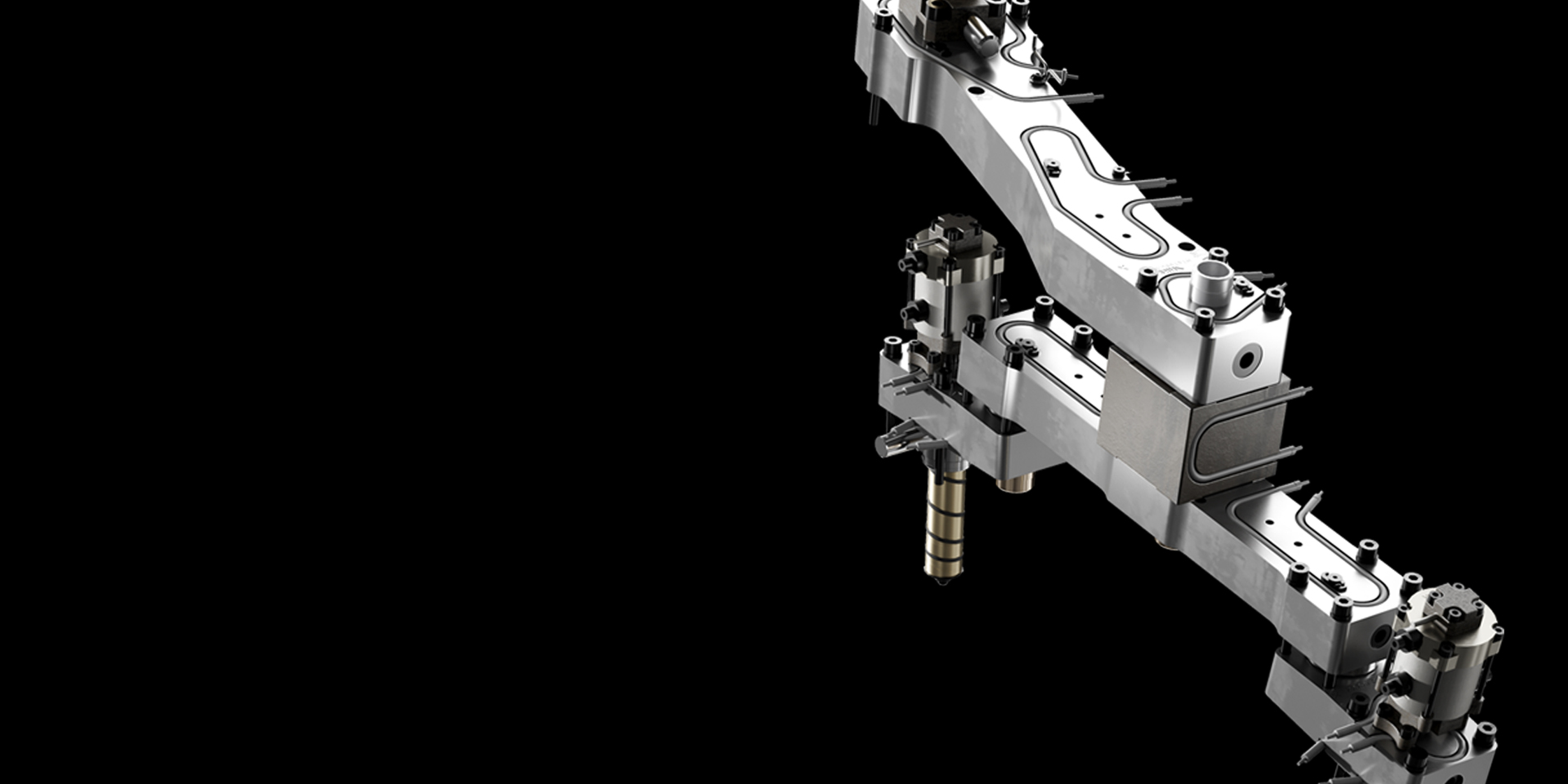

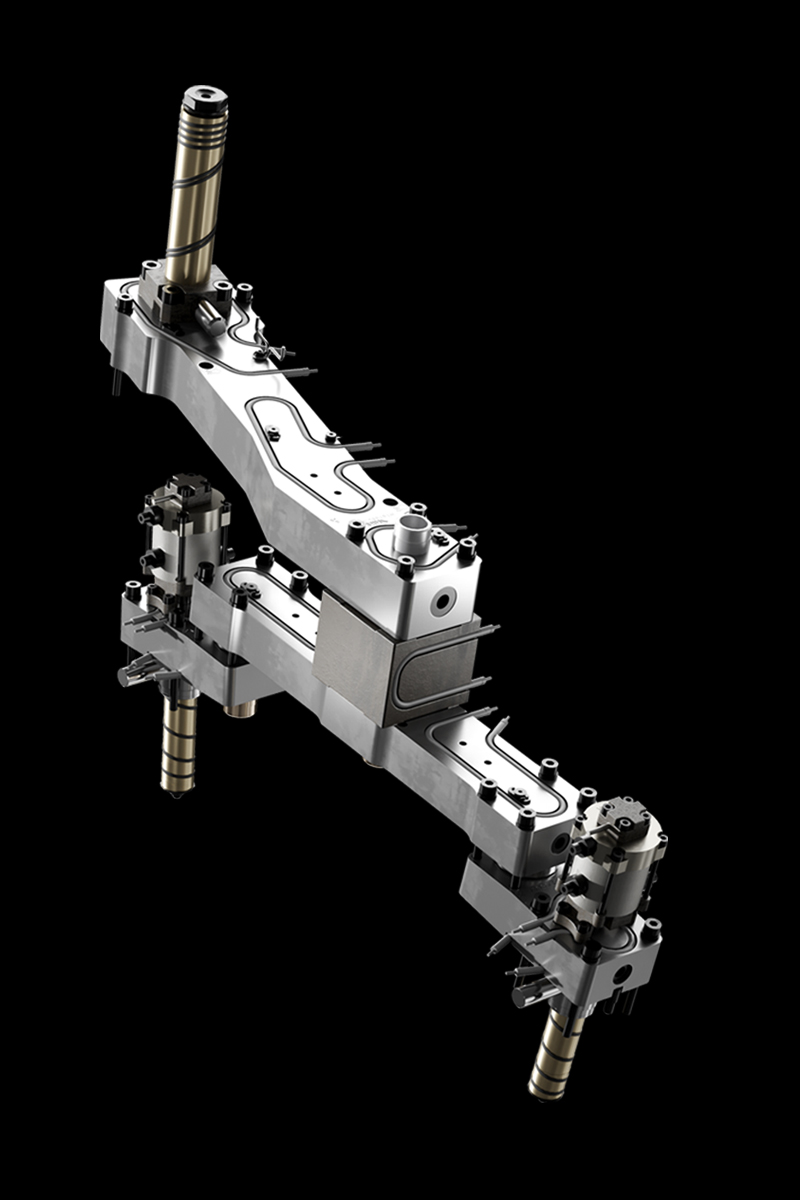

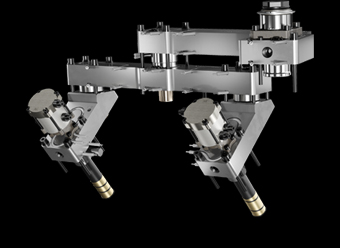

Suitable for rear and head lenses as well as for any lighting tool which is needed for complex shapes and angled nozzles.

Complex hot runner systems with injection points far from the injection machine inlet need a precise control of the thermal expansion of all the components.

With the target to keep this phenomenon under control, Oerlikon HRSflow developed specific engineering rules to design hot runner systems equipped with multiple layers, mutually connected. Multiple level engineering allows for well-balanced plastic flows in the hot runner and even pressure profile in the injection cavities. At the same time, strict design rules allow for a well-balanced system and the best thermal expansion control.

Multiple layer hot runners are widely used for rear and head lenses as well as for any lighting tool which is needed for complex shapes and angled nozzles, to guarantee a stable process and high-quality requirements.