The right device to reduce flowmarks in sequential filling

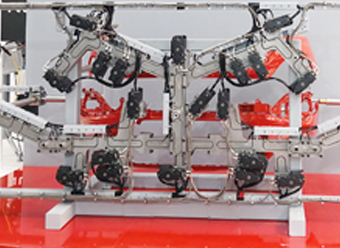

FLEXspeed technology has been developed to avoid the generation of flowmarks on the part surface generated by the instability of the plastic flow front in sequential moulding. This technology is recommended for medium to large size parts obtained through sequential moulding such as : embossed doors, not embossed bumpers, luggage covers, embossed IP, internal pillars (L >50cm), unpainted door treads, unpainted side skirts.

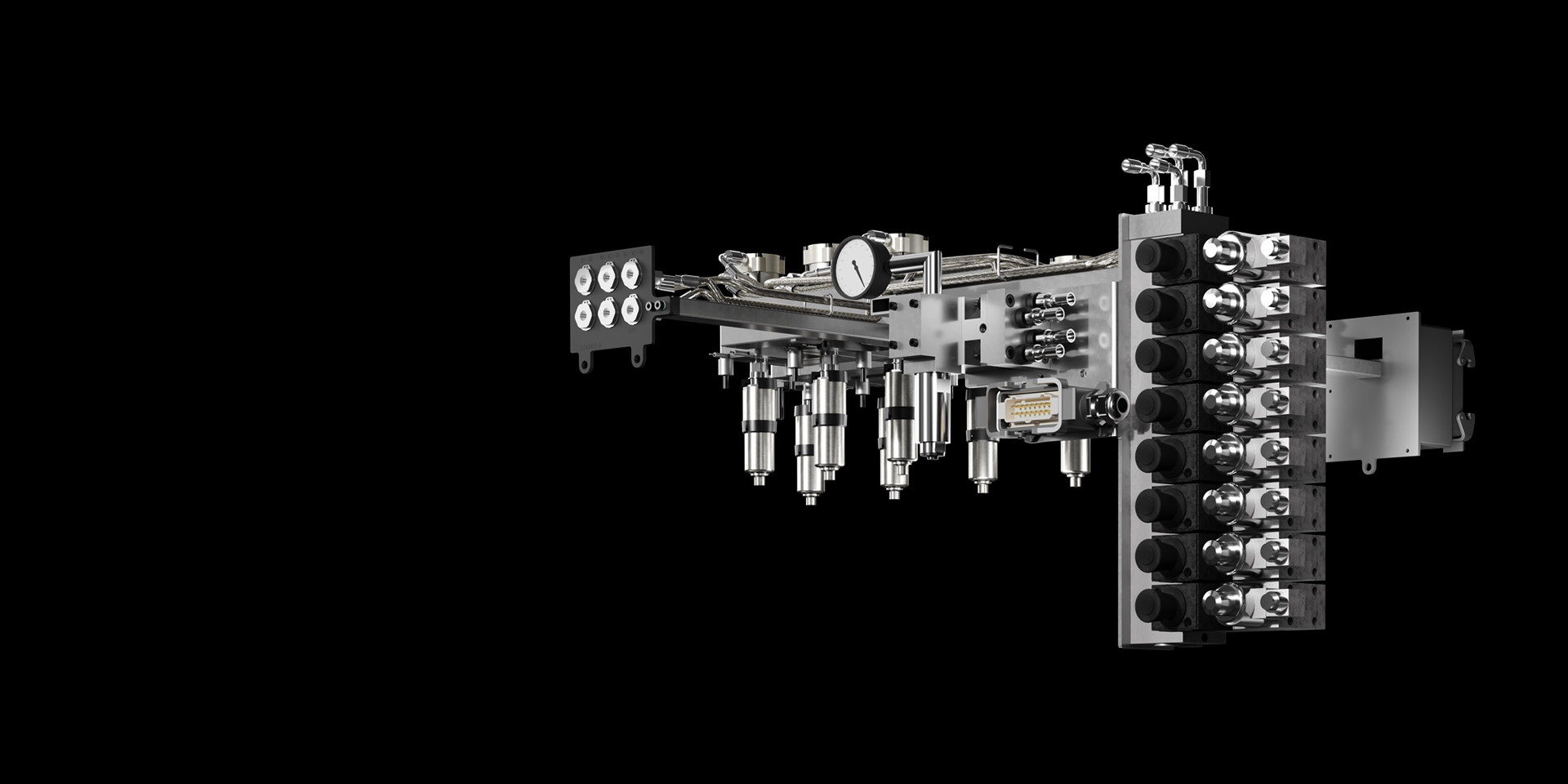

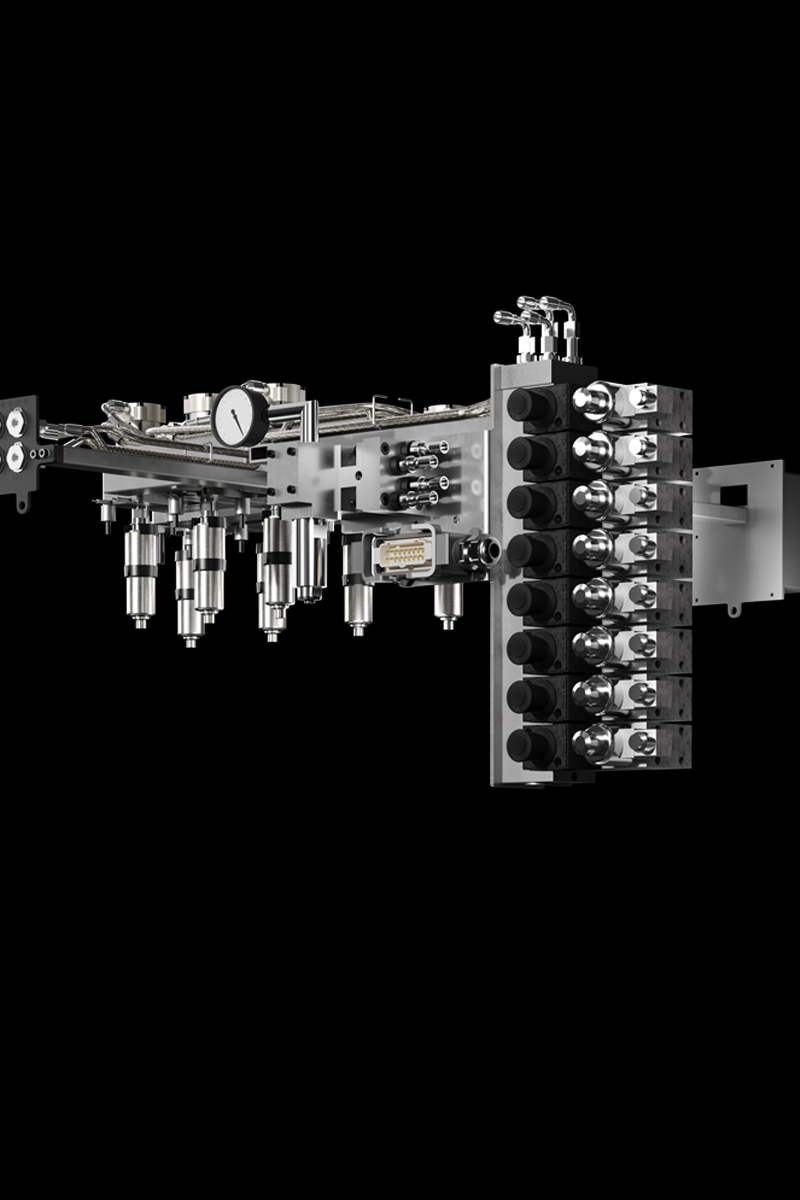

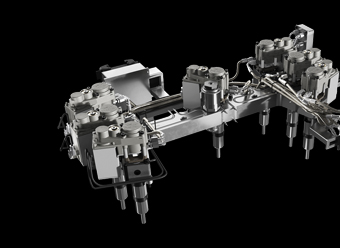

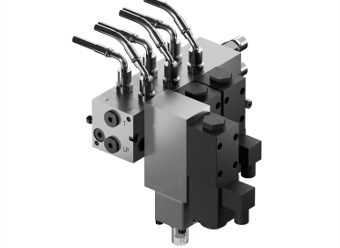

Pin speed setting can be done through an oil flow controller. When the cylinder is hydraulic, the technology is applied with the solenoid valves installed directly on the injection system and with external solenoid valves. A similar solution has been developed for the pneumatic activated systems.