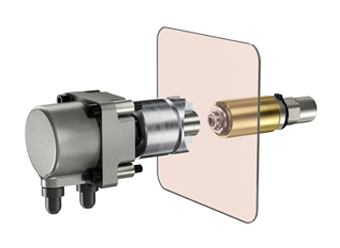

It enables hot runner systems with uncooled actuator

Designed for thermal insulation optimization, it avoids cooling for the most common automotive applications. A telescopic cover, made of a highly conductive material and placed between the actuator and the plate, makes a thermal bridge with the back plate to ease the heat dissipation.

Thanks to the new geometry of the components, HRScool Evo enlarges the range of applications where the active cooling can be avoided.

No pipe layout required for cooling. Actuators can be removed leaving the pin in the hot runner system. Available for hydraulic cylinders.

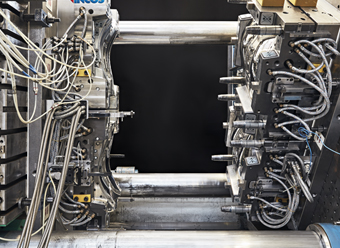

Committed to sustainability

- Lower heat dissipation of the manifold

- Reduction of the manufacturing time of the mold

- Reduction of the overall energy consumption (up to 10% per drop) according to the system dimensions and the applications

- Energy efficient solution

- Optimal thermal uniformity along the whole hot runner system