Suitable for processing techno-polymers applications

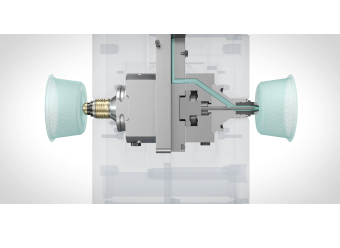

Suitable for processing techno-polymers applications, the new SA Nozzle Series is the ideal solution for technical applications with reduced weight (> 0.5 g) and thickness for all future challenges.

Main benefits

- High flow rate: thanks to wide channel section, it’s ideal for fast injection even with reinforced or viscous polymers.

- Compact solution: the reduction of the cut out allows for obtaining a compact seat of the mold and reduces the pitch between 2 adjacent nozzles.

- High pressure resistance: the screwed-in nozzle solution is highly reliable as minimize the possibility of material leakages due to tool machining mistakes or wrong assembly operations.

- High aesthetical quality of the part with reduced weight and thickness: SA Nozzle series has been optimized to reach the best thermal layout on nozzles ensuring the correct material management. Thanks to gate design is possible to inject components with a weight less than 1 gram and thickness less than 1 mm.

- Suitable for techno-polymers: thanks to the special design of the tip and the end ring, the temperature in the gate area is optimized to process techno-polymers with a narrow process window (such as PA66, PBT…)

Technical features

- Screwed-in solution.

- Available for Open Nozzle and Valve gate. All configurations are available with bushing through the cavity or gate on the cavity.

- Suitable for aesthetic parts, glass fiber and family tools.

- Ideal solution for overmolding, painting & coating.

- Available also for stack mold technology.

- Processable materials: PA6, PA66, PBT, POM, rubber, PP, PE, EPDM, ABS, PS, SAN, PC, PMMA and much more materials under evaluation of our application engineer experts.

Thermal gate injection

| Nozzle cut out |

Ø 20 mm |

| Nozzle lenght |

60 ÷ 210 mm |

| Ø Nozzle channel |

Ø 6 ÷ 4 mm |

| Hot runner manifold |

40 mm (cut out 65 mm) |

| Nozzle-inlet minimum pitch |

40 mm |

| Nozzle minimum pitch |

24 mm |

Valve gate injection

| Nozzle cut out |

Ø 20 mm |

| Nozzle lenght |

60 ÷ 210 mm |

| Ø Nozzle channel |

Ø 6 ÷ 5 mm |

| Hot runner manifold |

40 mm (min. cut out 120 mm) |

| Nozzle-inlet minimum pitch |

70 mm |

| Nozzle minimum pitch |

37 mm (on manifold) 46 mm (on plate) |

Field of application

Designed for technical and electronic components as well as small automotive parts such as exterior emblems, small interior switches, sound system knobs or tiny components in air-conditioning systems.