Our Solution

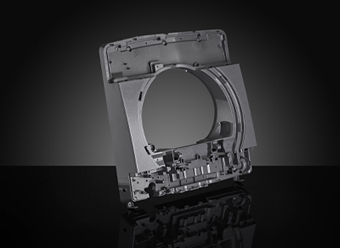

The maximum number of injection points was considered in order to provide a properly filled part.

A stack mould system with offset nozzles was selected to meet the request of high productivity and of a compact solution.

The solution selected was ideal for those parts where high structural resistance was required, because it injected the expected quantity of material.

The CAE analysis and the pressure loss calculation provided:

- The number of injection points and their location.

- The filling sequence.

- The deformation areas and possible weak points in the structure. It was possible to suggest the proper cooling line on the mould

- The correct flow diameter and system layout to obtain a fast color change

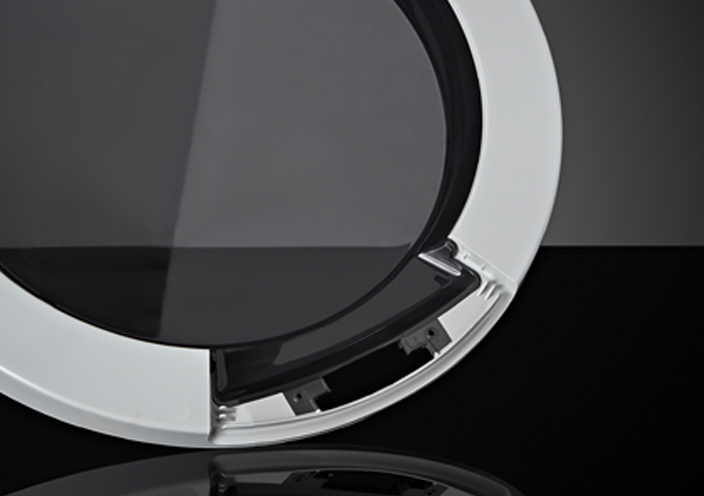

Oerlikon HRSflow system

- The hot runner system was composed by 1 single nozzle co-axial valve gate Gs series with gate diameter 5mm used as transfer system.

- 10 drops (5 + 5) conical valve gate Ma series with gate diameter Ø3mm and through the cavity end ring.

- Stack Mold with offset nozzles.

- The full system was pneumatic.