Our Solution

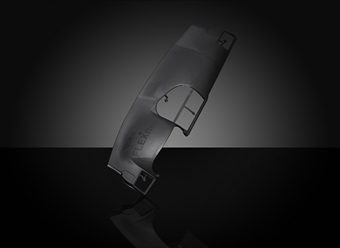

The MJA [MicroJect Advanced] door panel is produced through a FLEXflow 9 drop hot runner system installed in a prototype aluminium tool. The cavity features 4 different textures: two textile grains, one deep leather grain in the top roll and a carbon texture as decorative strip.

The door panel trim is 23% lighter compared to the traditional injection molding thanks to the thin-wall design and the integral foam structure. The choice of the servo-driven valve gate solution is due to its accurate valve gate control essential to meet the foaming performance. Moreover, thanks to FLEXflow high process repeatability and its precise control of flow rates at each individual gate during the injection process, the result is a lightweight Class “A” surface. Against standard injection moulding, FLEXflow technology can save a lot of energy promoting a lower demand for Injection Molding Machine clamping force.

Oerlikon HRSflow system

Hot runner system: FLEXflow 9 drops system Ga series, Conical Valve gate