Stop by Hall 1, Booth G31!

It's that time again! After a 4-year Corona break, Oerlikon HRSflow (L-Bank Forum/Hall 1, Booth G31) will be exhibiting at Moulding Expo from June 13 – 16, 2023 in Stuttgart!

Meet the entire value chain of the tool, pattern and mould making industry on site and find out about innovative product developments, new technologies, resource-saving processes, solutions for digitalization and much more!

Oerlikon HRSflow - represented by its DACH subsidiary HRSflow GmbH - specializes in advanced hot runner solutions for a wide range of applications in the plastic industry. "At our booth, we will provide an overview of solutions for multi-cavity applications, thin-wall applications in the packaging industry, solutions for small shot weights in the field of highly technical plastic applications, as well as family molds and functional film back injection," summarizes Stephan Berz, Vice President Sales Oerlikon HRSflow & General Manager HRSflow GmbH (DACH branch).

Booth highlights

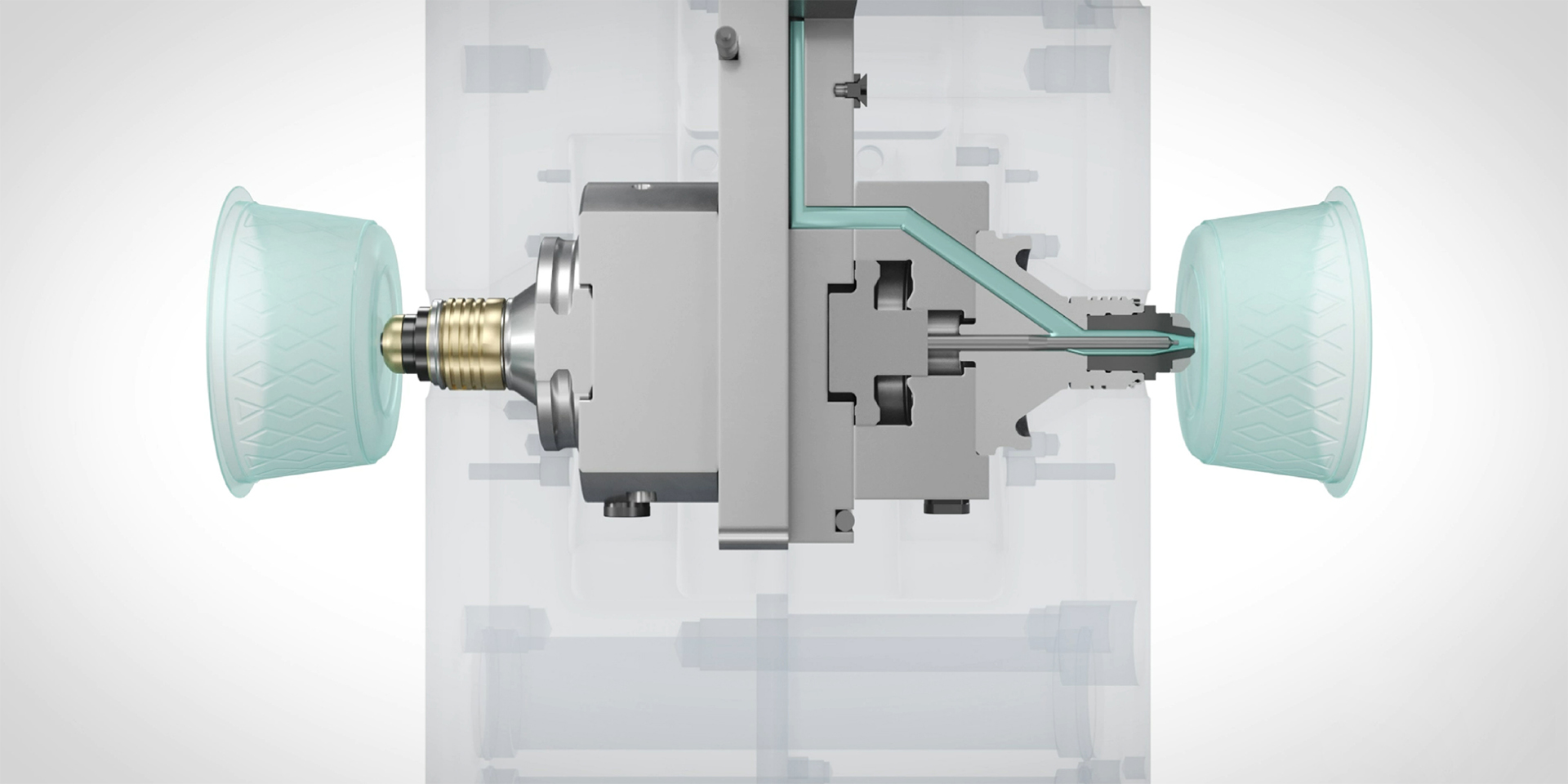

- The new Compact Stack Mold for thin-wall injection molding. Designed to withstand high filling pressures, this patent-pending solution enables fast cycle times without compromise on quality. Assembly and maintenance are extremely simplified and highly efficient thanks to a plug-and-play installation.

- Superior surface quality in the automotive industry. Among our hot runner solutions, the most revolutionary one is certainly FLEXflow. With its servo-electric needle positioning, it enables precisely controlled overmolding of the sensitive electronic components with high-quality surfaces at the same time. IMD (In-Mold-Decoration), FIM (Film Insert Molding) technology and family molds: discover the potential of this technology.

- High-performance systems for automotive technical parts. Suitable for abrasive and corrosive polymers, our hot runner solutions allow to manufacture quality parts with structural performance and dimensional stability keeping under control warpage and part deformation. Available at the booth, a 16 drop hot runner system designed for the injection molding of a cable holder made of PA66 + 30% GF.

Be sure to plan your visit to Moulding Expo, to stop by and meet us!

If you need a free entrance ticket, feel free to contact Grit Reifer, Marketing Manager DACH: grit.reifer@oerlikon.com!

We are looking forward to interesting discussions, in-depth questions and the pleasant atmosphere that we still remember from previous Moulding Expo events!