Our Solution

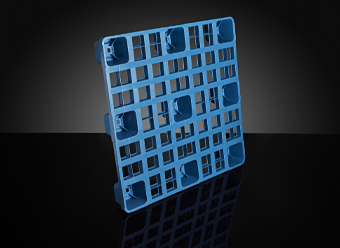

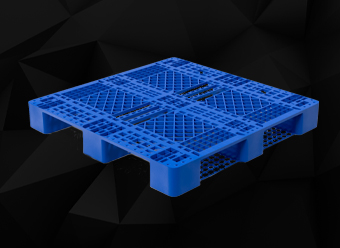

For the injection molding of this complex tool case, 4 hot runner systems from Oerlikon HRSflow are required. For the manufacturing of the two covers from a PC/ABS blend in a family mold, a 2 drops screwed-in system are used. Moreover a 3D Design Film is overmolded on the covers. Particular attention will be also given to the inner tray, the handle as well as the lateral latches made of PET RECOPOUND® by KURZ. The result is a stable and robust end product with illimited possibilities of decorations.

Oerlikon HRSflow system

For the production of the 2 covers with a family mold system (Molding material: PC + ABS) a 2 drops screwed-in hot runner system is used.

For the Internal component (Molding material: PET RECOPOUND® by KURZ) a 2 drops screwed - in hot runner system is employed.

For the Handle (PET RECOPOUND® by KURZ) a Single nozzle (Ms series, Torpedo) system is used.

For the production of the side latches (molding material: PET RECOPOUND® by KURZ) a single nozzle (Ms series, Torpedo) is employed.

Project partners: Arburg, Hofmann, LEONHARD KURZ, Oerlikon HRSflow