Our Solution

To avoid any sink mark it is important to balance the filling:

- It was selected 8 injection points.

- It was selected the gate diameter 2.5mm for increasing the shear rate (and subsequent temperature on gate area) because it is important to compensate the high viscosity of the PC material

- The cold runners profile was optimized.

For limiting the flow length, it was considered a multi-level manifold. It helped with balance too.

The mix of solutions selected was ideal for those parts with requirement of high structural resistance because it is injecting the expected quantity of material.

For check the absence of weld lines it was performed a CAE analysis. Using the analysis result was possible to suggest the proper cooling line on the mould.

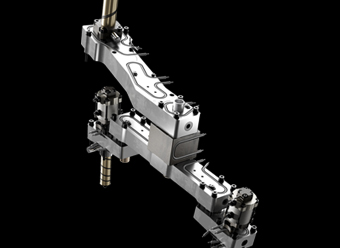

Oerlikon HRSflow system

The hot runner system was composed by 8 drops M series with 2 levels manifold. The gate diameter was 2.5 mm and it used free flow tip and external end ring.