Flexibly programmable, operated without control unit

FLEXflow One is the newest edition of our servo driven valve gate system where an additional control unit is not required during the injection process. It is as easy to use as the hydraulic/pneumatic system but with the advanced features of the electrical solution.

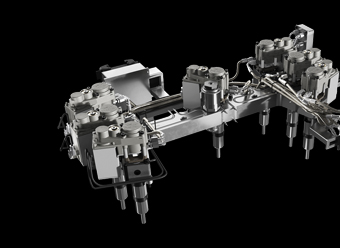

The heart of technology

All the settings (valve pin stroke and force) are saved in a Driver Module assembled on the mold. In its current design, this module comes with a default setting that fully opens/closes the needle. The servo-electric drive precisely controls the melt flow providing highly reproducible quality parts.

One device, countless possibilities

Using a hand-held External Smart Interface (E.S.I.) – which is briefly connected to the driver module - needle stroke and force can be individually set for specific applications, including multiple steps if required.

A safe and reliable injection molding process

Connected with the safety circuit monitoring the status of the IMM guards, the Safety Interface Box (or S.I.B.) is the device that assures power supply and operator safety.

The S.I.B. also protects each drive module present on the mold. S.I.B. size depends on the number of driver modules to control.