Maximum system performance for color change

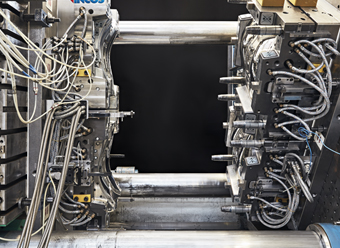

Optimization of color change affects the entire hot runner, with special focus on the nozzle. The objective is to offer maximum system performance for color change.

By means of suitable FEM analysis, followed by rigorous tests in the R&D department, the various solutions are tested. The bore channel sizing and channel finish is designed according to the type of material to be processed. Special attention is focused on the gate zone, which is accordingly shaped for the purpose of using insulation rings.

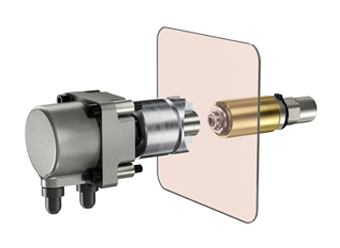

With FLEXflow, color change optimization becomes fast and in one touch

Thanks to FLEXflow Technology, the number of shots during color change can be reduced. The color change function on the FLEXflow Control Unit helps the operator automatically set the nozzle sequence and obtain the optimized color change procedure. Moreover, the operator no longer needs to set the nozzle opening sequence parameters every time, since the recipe can be automatically recalled whenever the color change is required.