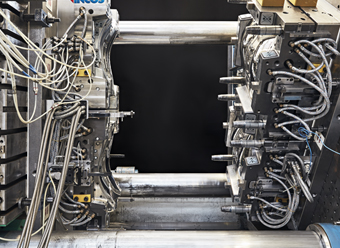

Mold cooling optimization

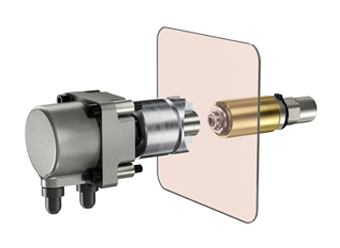

Selective Laser Melting technology, or SLM as it is commonly referred to, is an innovative process used to produce metal parts.

Unlike traditional machine tooling which involves removing shavings, SLM produces metal parts by the gradual addition of successive layers of laser-melted powder.

The advantage of SLM lies in the opportunity to develop inserts that can closely follow the geometric shape of cooling circuits rather than being constrained to straight lines.

Unlike traditional cooling circuits, SLM inserts enable users to achieve uniform mold temperature distribution.